Jonathon Pullen

Technical Services Manager

Gulf Coast District

The Infamous E1: Part 1

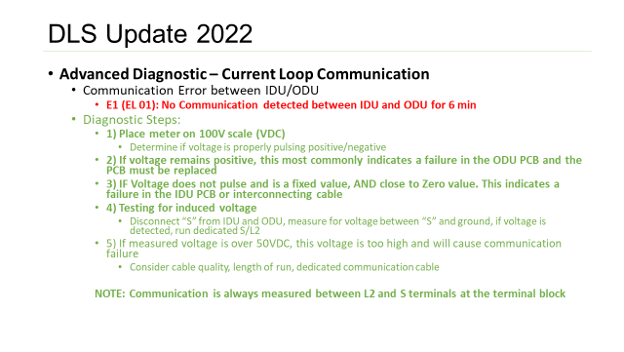

First, what is an E1 fault code? E1 is a ductless system communication fault between the indoor and outdoor units. Are you having a nuisance E1 after you replaced the circuit boards? Did you retro fit a ductless system using the existing wire and line set and received the infamous E1?

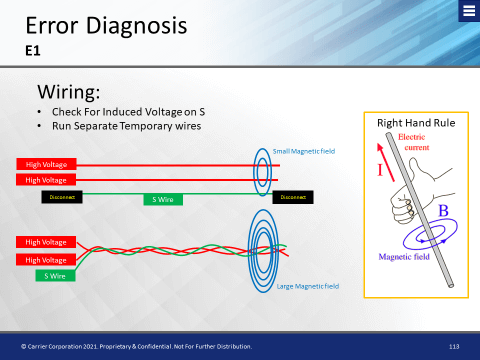

E1 from an induced voltage will cause communication problems with your new ductless system whether it is a brand new install or a retro fit change out. The problem is the wires inside the sheathing are twisted together causing an induced voltage on the “S” wire or signal wire. A 20 VAC and above will kill or scramble the signal causing a communication fault between the indoor and outdoor unit.

The way we check for this is to turn power off to the system, disconnect the “S” wire or the number “3” wire from both units. You may see the “S” wire or the number “3” wire depending on how the unit was labeled. Make sure the “S” wire does not touch anything when disconnected! Then turn power back on. I want to ensure you are cautious and aware: you are working on LIVE equipment! Set your multimeter to Volts AC with an alligator clip on one lead connected to the “S” wire and the other lead to ground; measure the induced current. It is preferred the reading is 0 volts, however, anything under 20VAC is acceptable. This problem has occurred due to using the wrong type 14/4 wire as well as using 18/8 wire. The use of the 18/8 wire is incorrect and dangerous!

The way to correct this problem is by replacing the indoor unit wire with the correct 14/4 wire. It is recommend using Duckt-strip brand wire due to its flat 4-wire design. Also, the Duckt-strip will not self-induce voltage into the “S” wire. Something to remember when installing a ductless product: it is best not to run the wire next to other high voltage wires. This can cause an induced voltage as well.

More to explore

2025 Rooftop Roundup

Get paid to upgrade your rooftop units with Mingledorff’s Rooftop Roundup! Earn $10 per ton when you purchase qualifying Carrier rooftop units

Monthly Promos

April 2025 Honeywell Thermostat Promo Through April! Buy 10 participating Honeywell thermostats and get 2 for just a penny! Cannot mix and

February Totaline® Chemicals Promo

Buy 3, Get 1 for a Penny – Stock Up Now! https://www.mingledorffs.com/wp-content/uploads/2025/02/jenny_brown_-_totaline_coil_cleaner_promotion_samples-1080p-1.mp4 📅 Promo Details: Offer valid: February 1 – February 28,